Home-made Dry Leaves Crusher

– Ratna Gokhale.

A professor of Mathematics, a passionate gardener. Her background of mathematics is evident in the experiments she has done in her garden, the precision, analysis; Her garden is a living laboratory. In the next week’s blog, we will visit her garden. Here is the blog by her about the crusher she and her husband made at home, re-using much of the available material.

Volume of dry leaves is overwhelming and proves a major challenge. I am sure this blog will help and inspire many to build their own leaf crusher.

Ratna Tai, thanks for being a guest blogger for Brown Leaf

Since 2013 I have been seriously pursuing home-composting for my self-cultivated organic garden at my apartment terrace. I am also a member of Organic Gardening Group (OGG) and Brown Leaf group through which I receive very useful ideas and experiences of like-minded people in this field.

During December 2015, I started adopting the method of 30:1 Carbon/Nitrogen composting which requires regular supply of large quantities of dry leaves as these are good sources of Carbon. My membership of Brown Leaf group was very useful to meet this demand.

But storing dry leaves requires huge space, so my immediate problem was how to store them within the limited space of my terrace. One option was to get the dry leaves crushed from some other members of Brown Leaf group who were having heavy- duty crushers. But that was working out very cumbersome and time consuming for me.

That’s when I thought – why not make my own crusher at home to meet my gardening compost needs? I ‘google’-d to check if any DIY kits were available for this purpose but alas with no luck. So “as usual” I bothered and pestered my husband to help me by building one at home and that too by adopting RRR (Recycle, Reuse, Repair) principle – i.e. making maximum use of recyclable waste items at home! My husband is an engineer by profession and always feels challenged by RRR ideas! He recalled that his brother-in-law (Mr. Mohan Karmarkar) had in the past attempted building a cutter at home using an electric hand-drill machine and then we both got obsessed with taking the same concept forward for our dream product in pure RRR style.

The first step to any creativity is always ‘mental visualization’ of end-product! We “visualized” our dry- leaf crusher to be like a hand-held kitchen-blender but with a much powerful motor, a crushing-can much bigger in size and the blades much longer and more powerful!

We had an electric hand-drill machine at home which we felt would comfortably meet the first requirement of high drive power. But the main question was – which common household waste products could be adopted to build large shredding-can and the cutting blades? There is a saying that “a challenged mind is often an inventor’s workshop”!

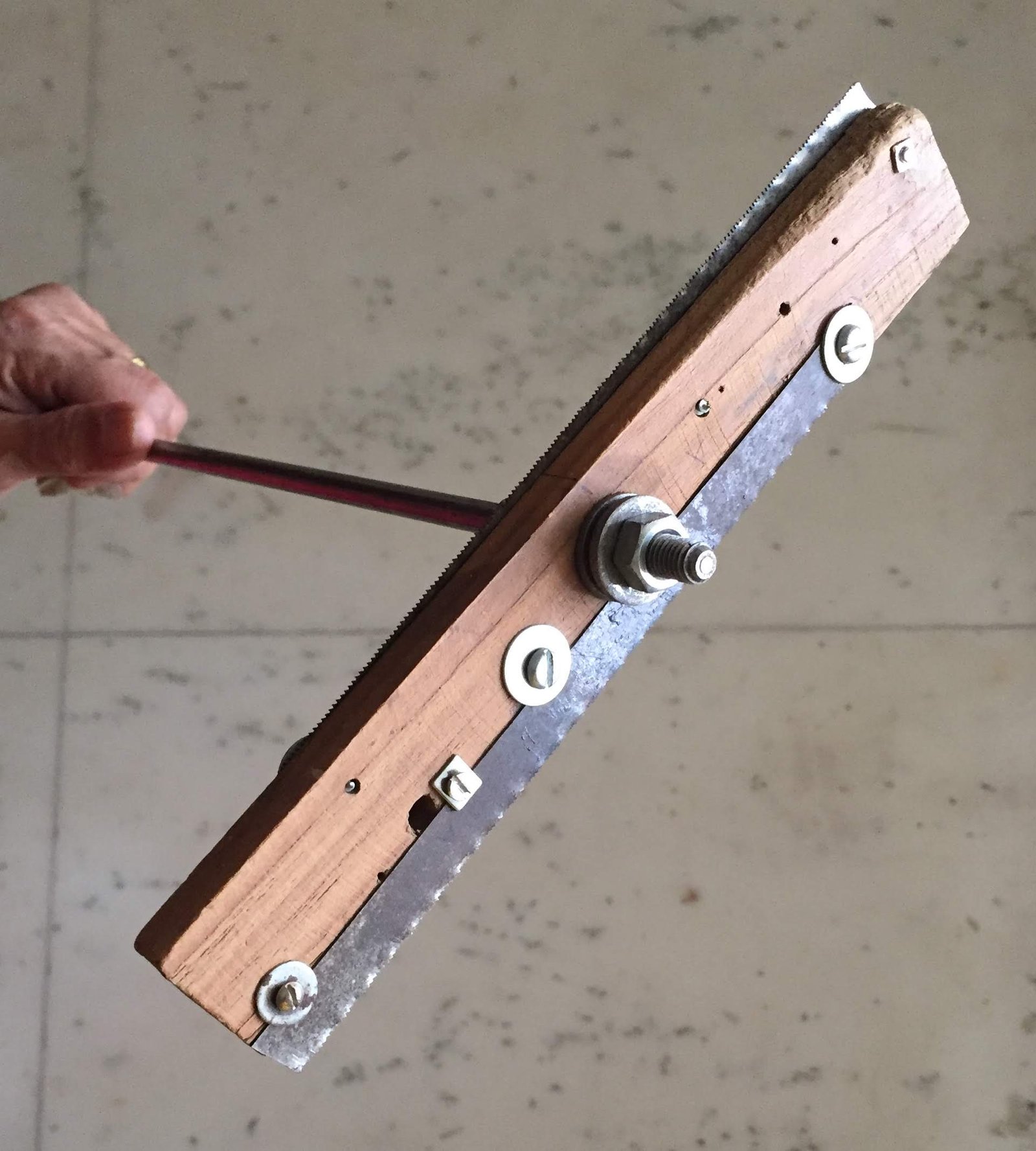

We soon hit upon an idea of using an old Asian Paints can – that was lying unused inside our scrap item’s shelf – to be our make-shift crushing-can and using an old partially-rusted (!) hacksaw blade – lying helplessly in our tool-box – as the cutting element! We also traced a small 10 inch-long piece of wooden baton that would serve as the “base” for mounting the hack-saw blades. Excited with such self- nurtured idea of reuse and an additional bout of engineering-mind to put together the items with use of screws and nuts, we soon crafted a “blade assembly” through some trial and error experimentation

The next bigger challenge was how to find a sturdy metallic spindle to connect the blade assembly to the clutch of the drilling machine! Sturdy metallic spindles are rarely available in any household waste and so we approached a commercial lathe-workshop at Shivajinagar to get it specially manufactured for us. But they quoted Rs. 350 for just one 14-inch steel rod! We concluded that to be too costly and not an elegant solution! So, then what would be a good alternative? This challenge made us spend another round of sleepless nights in deep thoughts, but thankfully my husband hit upon a nice solution! How about using a ‘standard threaded tie-rod’ which is normally used for firmly fixing water-pumps to their grouted foundation? Such tie-rods are manufactured in standard lengths with end-threading and are hence are cheaply available in market! Thrilled with this idea, we immediately drove to Bohri-Aali (area in Pune city) where there are many water-pump accessory shops. Soon we found what we wanted and happily returned home with a tie-rod costing just 80 rupees (!) plus necessary nut-bolts and washers that were to form the spindle of our dream machine! A few hours of concentrated craftsmanship at home and our dream machine was ready!

Now came the testing time – the real proof of our self-cooked pudding! 😊

Excited and eager to see the result of our creativity, we filled the paint-can with dry leaves –right up to its brim. Then we inserted the blade/spindle assembly through a pre-drilled hole of the can-cover and fitted the blade assembly into the clutch of the electric drill! With throbbing hearts we then inserted the blade assembly into the can of dry-leaves and fitted the lid onto the can. Holding the drill machine vertically steady with one hand and the power-switch of the machine with another, we were all set to conduct first trial-run of our dream product! Would is crush the leaves nicely as desired, or would it instead crush our dream idea itself – the ‘moment of truth’ was staring in our eyes! Would Thomas Alva Edison have felt as nervous as us while inventing the electric bulb? – a silly thought cropped in my mind! Finally, with a bout of courage, my husband pressed the power knob of the drilling machine. The machine started with a strong jerk but soon stabilized into a steady roar with noise of leaves and twigs getting cut at high speed! In a few seconds we were able to lower the spinning rod slowly but steadily deeper into the can till it almost touched it floor in just about 20 seconds. We then switched off the drilling machine, slowly lifted the lid and blade assembly out of the can, and as the leaves-dust settled inside the can we were able to see mass of crushed leaves at the bottom of the can!

A can-full volume of dry leaves had got crushed and reduced to one-third of its original volume in just 20 seconds! Viola! Our dream machine had indeed worked!!

Although I was thoroughly happy with the result, my husband wasn’t fully satisfied with its performance! He found a need to eliminate the machine vibrations which he had sensed during the spinning of the spindle. The vibrations were indicative of some imbalance in the blade assembly – which if left uncorrected – would ultimately lead to breaking-off the blades! So some more tweaking of design had to be carried out, requiring some more ideas and trial-and-error experimentations! Finally, desired level of balancing was obtained through a very simple method of drilling 1-2 small dummy holes on the wooden baton to realize equal weight on either side of the spindle. Such balancing of blade design eliminated the undesirable vibrations.

Since then we have used our home-made leaf crusher very regularly – at least on 40-50 occasions so far. It has always been a very satisfying and rewarding experience for both of us!

Here is the video of the leaf crusher in action

https://photos.app.goo.gl/NTJ3sWZkH6D5usxi8

I am interested . I could do it. But how to use brown leaf for gardening.

Let me know the process through video.

My activities..

Ulhas river Swachata abhiyan.

Brown leaves can be used for garden through Mulching and Composting. Compost made from dry leaves can be used along with soil or in place of soil as well. It provides sufficient nutrients, is very light in weight hence especially suitable for terrace gardens. In your case, you can even compost dry leaves and Pistia that you remove from Ulhas river. Select a spot outside riverbed, make alternate layers using dry leaves from nearby trees and pistia. Pistia will provide required moisture. Later on, in June, just before monsoon, you can plant saplings there. Sharing a few links for you. Also sharing link to a guide that details how you can use dry leaves.

https://brownleaf.org/blogs-for-members/

https://brownleaf.org/wp-content/uploads/2018/10/How-to-manage-dry-leaves.pdf